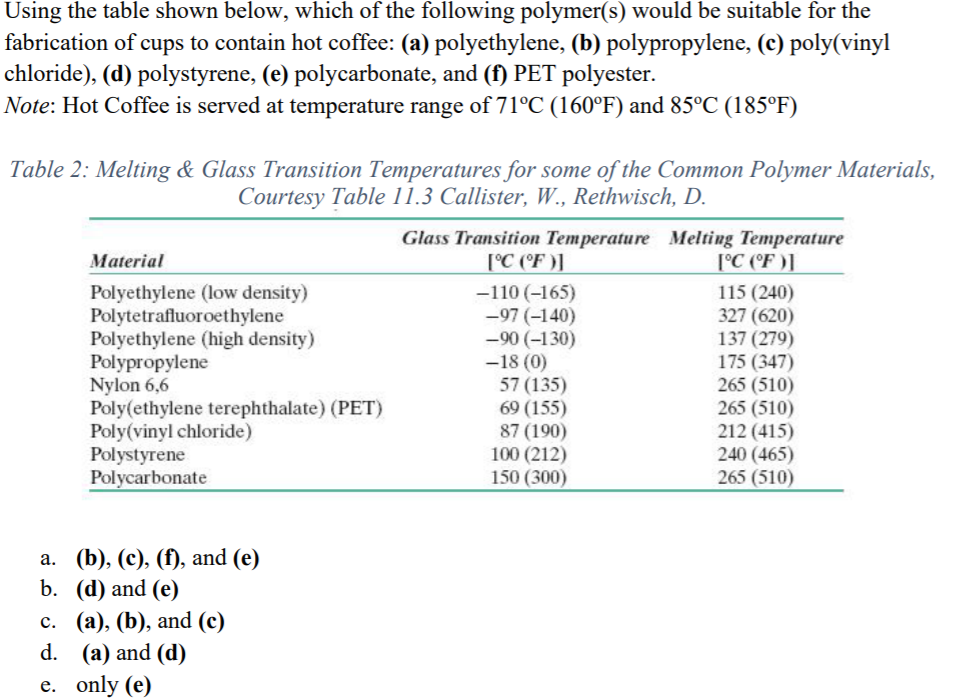

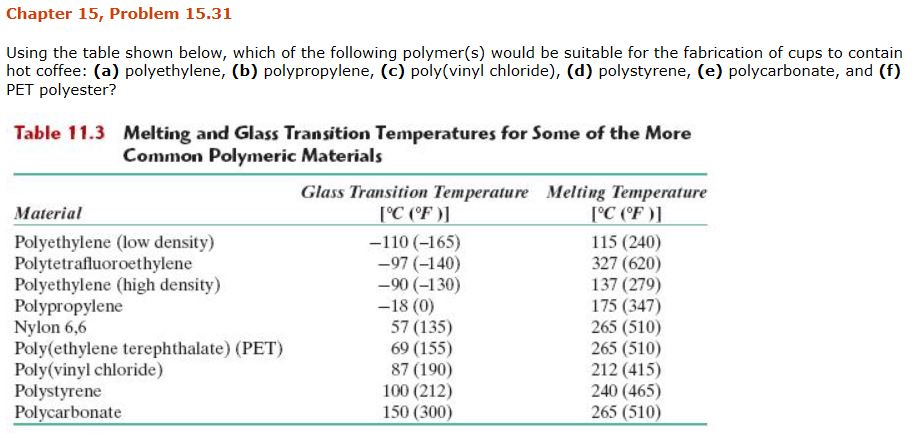

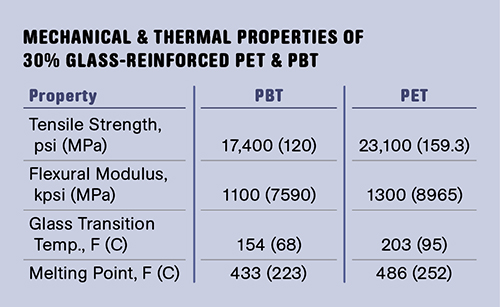

Explain the differences observed in the Tg and Tm values for each pair of polymers: (a) polyester A and PET. (b) polyester A and nylon 6,6. (c) How would you expect the

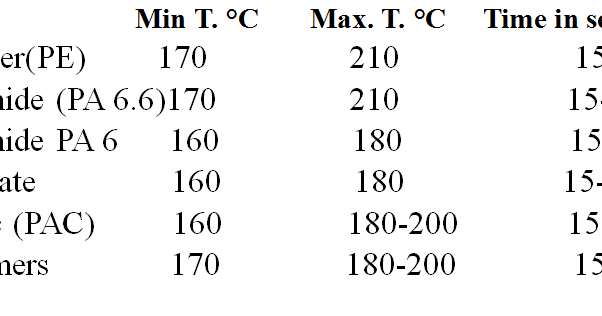

![PDF] Dyeing of Flame Retardant Polyester Fabric developed by using Low- melting-point Bicomponent Filament | Semantic Scholar PDF] Dyeing of Flame Retardant Polyester Fabric developed by using Low- melting-point Bicomponent Filament | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/a2f5ef8b7a099074d8e48bd9e483c711338b04c8/2-Table1-1.png)

PDF] Dyeing of Flame Retardant Polyester Fabric developed by using Low- melting-point Bicomponent Filament | Semantic Scholar

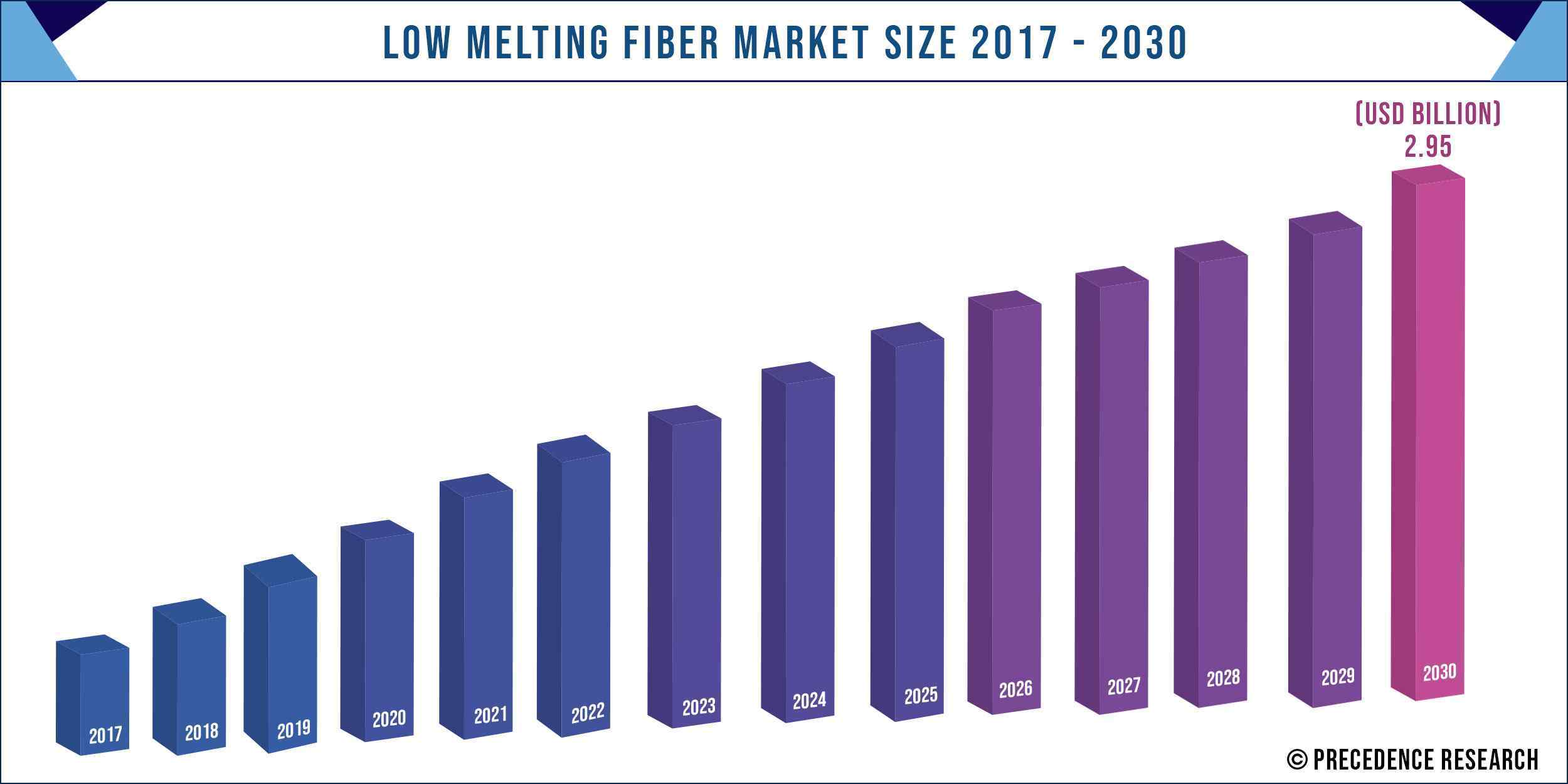

Comparision Between Low Melt Fiber and Bi-Component Fiber - POLYESTER STAPLE FIBER HOLLOW CONJUGATED FIBER

Bio-Based Polyesters with High Glass-Transition Temperatures and Gas Barrier Properties Derived from Renewable Rigid Tricyclic Diacid or Tetracyclic Anhydride | Macromolecules

Polymers | Free Full-Text | Preparation and Characterization of Hot Melt Copolyester (PBTI) Ultrafine Particles and Their Effect on the Anti-Pilling Performance of Polyester/Cotton Fabrics

Variation of Melting Temperature of Polyester Thermoplastic Elastomer... | Download Scientific Diagram

Thermograms of the polyester resin and the reinforcing PET yarn before... | Download Scientific Diagram

Development of structure–property relationships that allow independent control of glass transition temperature, melting temperature, and rheology in a library of bio-based succinate polyester polyols - ScienceDirect

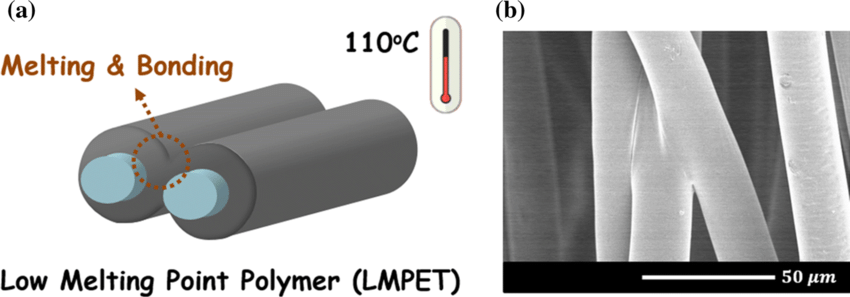

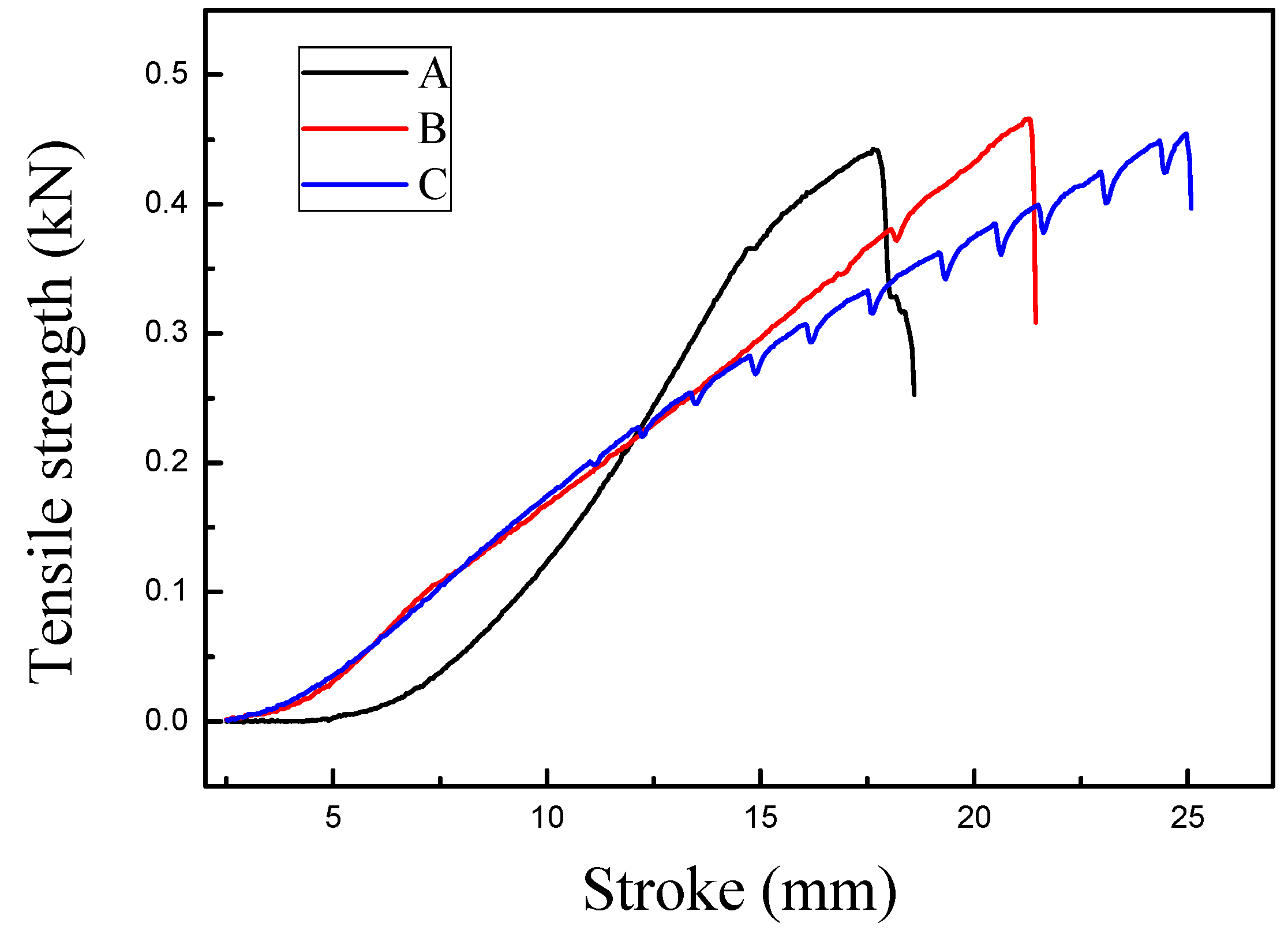

Polymers | Free Full-Text | A Study on Carbon Fiber Composites with Low- Melting-Point Polyester Nonwoven Fabric Reinforcement: A Highly Effective Electromagnetic Wave Shield Textile Material

![PDF] Comparison of Nylon , Polyester , and Olefin Fibers Using FTIR and Melting | Semantic Scholar PDF] Comparison of Nylon , Polyester , and Olefin Fibers Using FTIR and Melting | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/6aedb26ad088c1540133b066087c7b303684572f/30-Table2-1.png)

.jpg)